MANUFACTURING

Agile Electronics Manufacturing Service - EMS

Powered by

ISO 9001

ISO 13485

TECHTO Electronics offers comprehensive electronics manufacturing services to provide customers with a seamless and cost-effective experience. We offer tailored solutions for both high-volume production runs and smaller batch orders.

Our agile electronics manufacturing approach enables us to deliver rapid prototyping, efficient production, continuous improvement, and shorter lead times. We can easily scale our production to meet customer needs and quickly adapt to market changes. Our experienced team will guide you through every stage of the production process to ensure that you bring top-quality compliant products to market in the shortest time possible.

We specialize in

- Design optimization

- Components sourcing

- Supply chain management

- Box-build assembly

- End-of-line testing

- Retail packaging

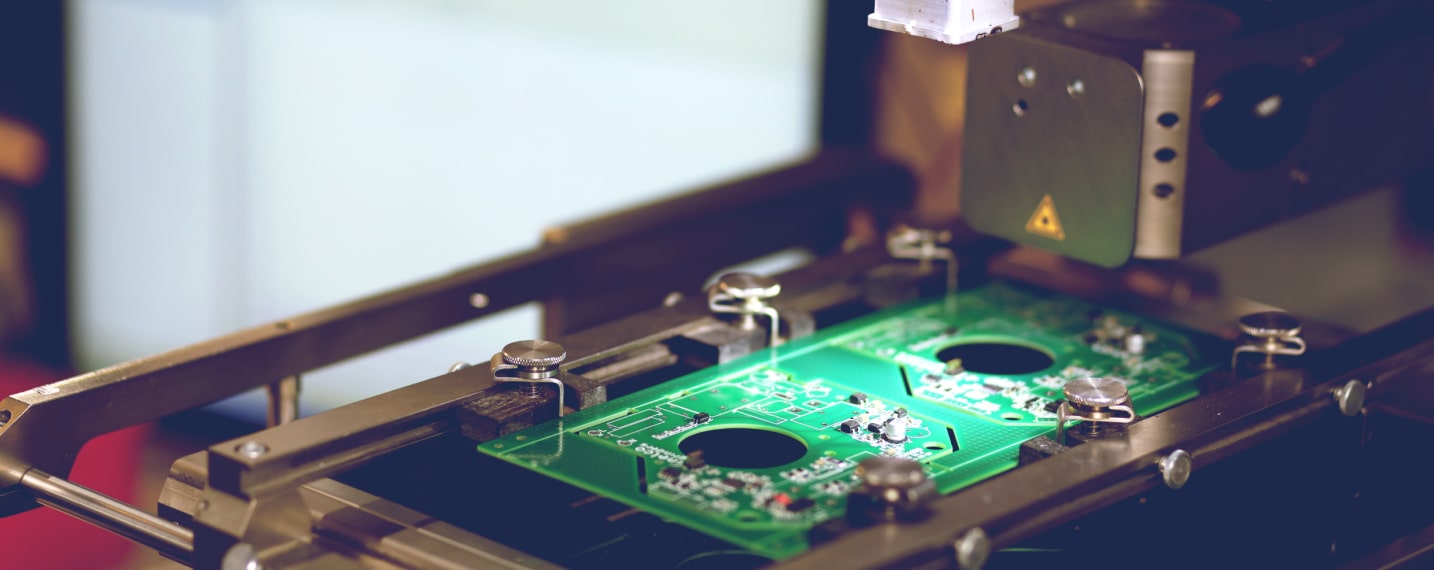

PCB ASSEMBLY & TESTING

EKTOS’ Electronic Manufacturing Service (EMS) has been providing high-quality PCB assemblies that meet the IPC-A-610 class 2 and 3 soldering standards for several years. Apart from conventional PCB assembly, we also offer customized testing of PCBAs to meet customers’ requirements. This is achieved by using either custom-made rigs or EKTOS’ innovative Product Test System (PTS).

Our PTS is designed to enable quick and efficient testing of critical features that customers have selected, ensuring cost-effective test setup, especially when introducing new products to the market.

EKTOS specializes in conventional electronics, medico, and power electronics assembly.

MEDICO

TECHTO Electronics is an ISO 13485-certified company that is capable of PCB level and whole product level assembly. Ensuring a dust-free assembly zone and cleaning methods allow the assembly of demanding products.

POWER

MANUFACTURING CAPABILITIES

THD Soldering

We ensure secure electrical connections between the components and the PCB, allowing for reliable and durable electronic assemblies for your products with THD soldering, or Through-Hole Device soldering. It involves soldering electronic components with leads that pass through holes in the printed circuit board (PCB). This method is typically used for larger components and offers strong mechanical stability.

PCBA Conformal Coating

PCBA conformal coating is a protective layer applied to PCB assemblies to safeguard against environmental factors. The coating material is typically a thin, transparent layer that conforms to the contours of the PCB and its components. It insulates, prevents corrosion, and enhances reliability without impacting electrical functionality.

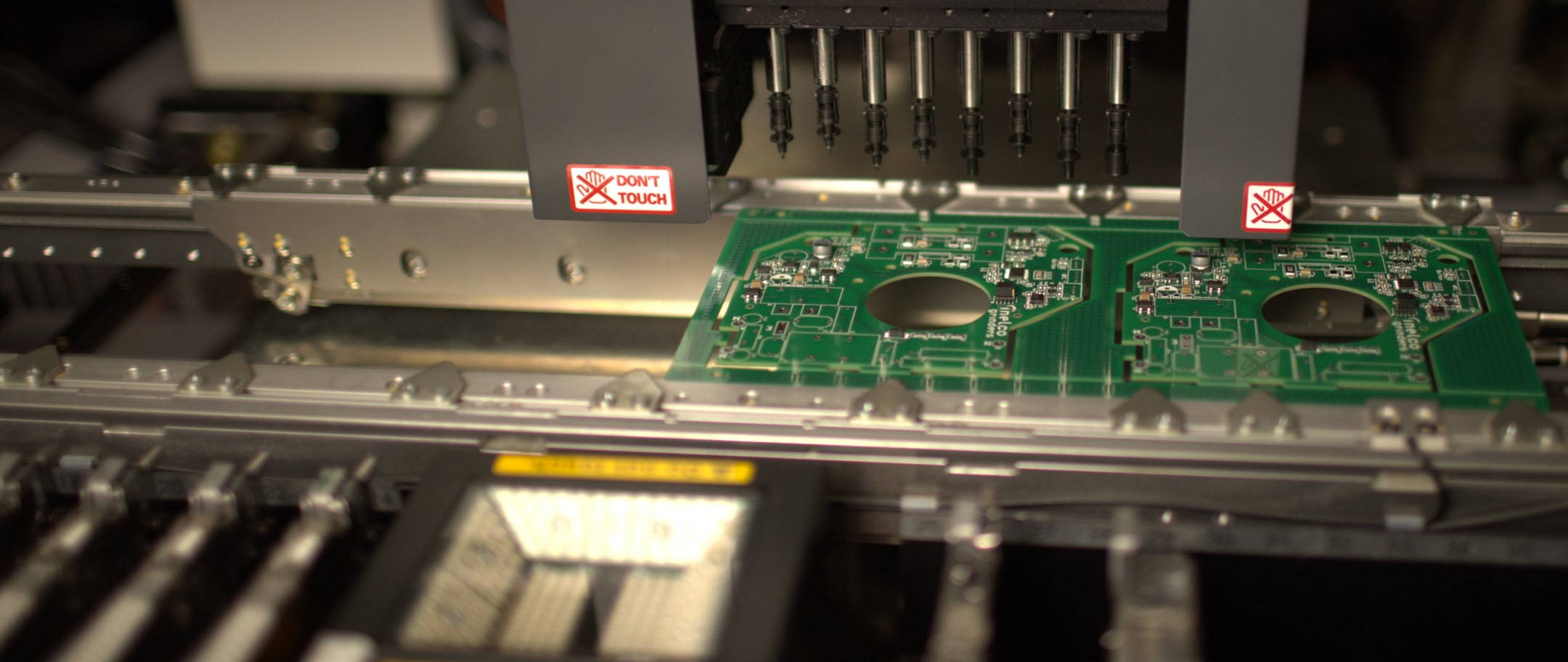

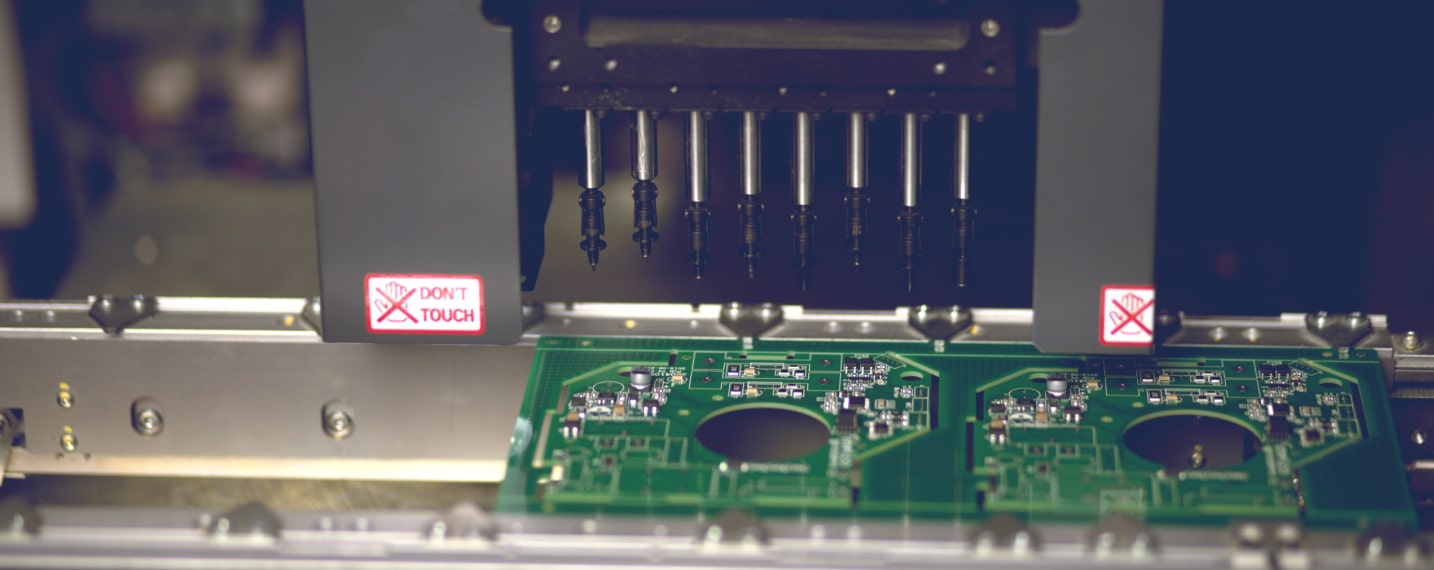

SMT Assembly

Using SMT assembly, we can produce your intricately designed and compact electronics. SMT entails mounting tiny components directly onto PCBs, eliminating the need for drilled holes and enabling sleek. Our skilled technicians utilize cutting-edge machinery and robotics for precise placement and reliable connection.

Retail Packaging

We provide safe and secure storage, transportation, and distribution of electronic assemblies, protecting them from damage and hazards, and ensuring that they reach customers in optimal condition.

In-line QC automatic optical inspection

To ensure high-quality standards during the production process, we rely on automated optical inspection systems. These systems use advanced imaging technologies to inspect electronic components and assemblies for defects, such as missing or misaligned components, soldering issues, and other visual anomalies. The inspection is carried out in real-time as the products move along the production line, enabling us to promptly detect and fix any faults without compromising the efficiency of the production process.

Wave Soldering

Wave soldering is a type of soldering process used in electronics manufacturing. It targets specific set of components on a PCB at once, applying solder to multiple designated components. This automated process offers speed, cost-efficiency and is suitable for assemblies with lots of THD components on one side of PCB.

Box – Build

We assemble and test complete electronic systems, integrating components, sub-assemblies, and modules into a finished product.

Our technicians specialize in enclosure assembly, wiring, cable harnessing, and hardware installation. Additionally, we ensure functionality, reliability, and compliance through testing and quality control measures, delivering fully operational electronic systems that meet specifications and standards.

Cable / Harness Mounting

Our team of technicians specializes in ensuring the efficient and reliable functionality of electronic assemblies by securely attaching cables or wiring harnesses to electronic devices. This involves preparing, connecting, routing, and fastening cables to their designated locations, ensuring proper electrical connections, organization, and protection. Rest assured that we will provide the necessary expertise and attention to detail to guarantee that your electronic devices are functioning optimally.

Purchasing & NPI

With our integrated approach, we procure materials and ensure a smooth transition from product design to manufacturing. This involves sourcing, supplier selection, order placement, and inventory management, along with activities such as prototype development, testing, and process optimization.

Functional Testing and Repair

Functional testing and repair are interconnected processes in electronics manufacturing. Functional testing evaluates product functionality to ensure it meets the specified requirements. Repair addresses detected faults or failures by diagnosing and fixing the identified issues to restore the product to its intended functionality.

TECHNICAL

CAPACITIES

3 high-efficiency Yamaha SMT machines in-line and BTU reflow

Fine pitch BGA 0.8 QFP/BGA

Complex repairs incl. BGA rework

Passive components up to 0201

BENEFITS of WORKING WITH EKTOS DEV TEAM

We prioritize flexibility, responsiveness, and adaptability in our production process. By utilizing advanced technologies, streamlined workflows, and collaborative practices, we swiftly respond to market demands and customer requirements. With a focus on efficiency, continuous improvement, and effective communication, we efficiently serve customers across various industries.

With Digital traceability, we track and trace electronic components and products throughout their lifecycle using digital technologies. It captures and stores data related to the manufacturing, distribution, and usage of these items. This is used to enhance transparency, improve quality control, and identify and address potential issues or recalls more efficiently. At the same time, it ensures compliance with regulatory requirements.

We ensure that cstomers receive rapid, precise quotatio ns for their electronics manufacturing needs. This streamlines customers‘ decision-making process and get project started sooner rather that later.

We deliver competitive pricing while maintaining quality standards in the mounting process. We offer cost-effective component mounting or assembly solutions at prices that are comparable to or on par with the pricing offered by Chinese manufacturers.

We ensure that cstomers receive rapid, precise quotatio ns for their electronics manufacturing needs. This streamlines customers‘ decision-making process and get project started sooner rather that later.

We deliver competitive pricing while maintaining quality standards in the mounting process. We offer cost-effective component mounting or assembly solutions at prices that are comparable to or on par with the pricing offered by Chinese manufacturers.

We prioritize flexibility, responsiveness, and adaptability in our production process. By utilizing advanced technologies, streamlined workflows, and collaborative practices, we swiftly respond to market demands and customer requirements. With a focus on efficiency, continuous improvement, and effective communication, we efficiently serve customers across various industries.

We consistently meet and exceed our customer expectations by delivering products within the agreed timeframe. Thanks to our agile approach, we communicate effectively, minimize lead times and enable quick responses to market demands. These helps us ensure timely delivery, customer satisfaction, and a competitive advantage.

MANUFACTURING FACILITIES and EQUIPMENTS

SUCCESS STORY

TECHTO accelerates time to market for AirWallet's cashless payment system for shared laundries

With our cooperation with EKTOS and TECHTO, our device hit the market within a short amount of time. We are able to maintain product cost on a competitive level and enjoy support for manufacturing over the years.”

Christian Mortensen, Co-Founder and CEO at AirWallet

QUALITY POLICY

Quality is at the heart of everything we do at TECHTO Electronics. Explore our commitment to excellence.

Read our Quality Policy here

CONTACT US

FEEDBACK

Help us enhance our services by sharing your valuable feedback.

Please take a moment to complete our Customer Satisfaction Questionnaire.

We genuinely appreciate your time in helping us serve you better.

Conveniently fill out the questionnaire here

FREQUENTLY ASKED QUESTIONS

Our Agile Manufacturing approach enables us to swiftly produce the first series of products to help you launch new products or their upgraded versions, faster than the majority of competitors. We seamlessly switch between products and satisfy each customer's unique needs. Beyond classic electronic manufacturing services, we can offer full assembly service for your product using our box-build and testing expertise. All our services are competitive in terms of both pricing and delivery times, benefiting from our proximity to the EU.

Yes. Despite the ongoing war in Ukraine, we maintain normal operations, having taken only a few basic security measures and having a full contingency plan. Our factory is in the Western part of the country, far from the frontline, and was not affected by war actions. Moreover, the city of our operations is considered one of the safest areas in the country. All electronics components as well as finished products moving to and from the factory are covered by our corporate insurance

We can do it all – from prints - to printed circuit board assemblies (PCBAs) to fully assembled products based on PCBAs made in the same factory. Apart from the production of electronics, we’re strong in box-build of electronics including testing after box-build and retail packaging. We can work both with your box-build components and packaging but are also able, in most cases, to source these from our network of suppliers.

In fact, we prefer to source all the parts ourselves which will be covered by our standard guarantee. You can also supply all the parts sourced on your own – our guarantee will then cover only mounting services according to applicable IPC standards and not the parts themselves. Upon special arrangements, we can work with a combination of customer and own materials.

Since EKTOS' establishment in 2008, we have been able to build a wide network of suppliers of PCBs, electronic components, mechanical and other parts normally used in the production of electronic products. All our active suppliers are verified through our supplier acceptance procedures. We source from all levels of the supply chain: producers, distributors, catalog suppliers, and proven brokers – to provide the best ratio of pricing and delivery times, without compromising on quality.

Normally, it takes up to 1 week to get an offer from us. Most of this time is needed to get information from the supplies for the components not available on the market instantly (there are often some) or get better prices from alternative suppliers.

Nowadays, it’s subject to the availability of components in your BOM on the market. If all are instantly available, the turn-key production first batch of first 10-100 units can take up to 4 weeks including the shipment from/to the EU.

From 1-3 prototypes to 10,000+ units in a single order – depending on the complexity of the product.

Our order processing and production systems are designed to be able to take in prototypes in between mass production orders. We regularly provide this service both to our in-house Electronics Development department and for third-party clients.

Our commercial offer normally consists of 3 lines: one-time cost, first batch price, and regular price. One-time costs include NPI (New Product Implementation) costs, including stencils, and tools/instruments that are specific to your product(s). This also includes processing your hardware documentation and import to our systems, programming SMT machines, and creating assembly and quality control instructions. The first batch price is our educated estimate based on some assumptions made w/o having produced the product before. The regular price is the expected price based on all optimizations implemented after the first batch order. We normally accept after-payment provided the cost of BOM as well as sourcing costs are covered by the prepayment (the size depends on the product).

If the components in your BOM are RoHS compliant, so is the assembly made in TECHTO. By default, we’re using only RoHS-compliant production materials and consumables.

Our factory is ISO 9001 (Quality Management System) and ISO 13485 (Medical Devices) certified. We uphold these standards which cover the provision of services for the contract production of electronic printed circuit boards with mounted components, enclosure assembly (box-build), programming, and testing of electronic products including those for applications in medical devices.

Various industries including energy, indoor climate, audio, energy, marine and defense, agriculture, IoT, LED, and healthcare. Regardless of your industry, our engineers specialize in tailoring solutions to meet your specific industry needs beyond the conventional.

Yes, these are available on the “Cases” page of our website

You can send your request for quotation to orderdesk@techto.eu and we will get back within 24 hours with a list of documentation and information we need to precisely estimate your order. The basic documentation requirements are BOM, Gerber, and P&P files, assembly instructions (if applicable), and a filled-out purchase order form.